About Us

About Green Filter

COMPANY PROFILE

Established in 2010, Zhejiang Zhenhang Filter Factory is a private

enterprise specialized in producing a series of filter products.

With our continuous efforts and the support from our customers, our factory covers over

10,000 square meters and has 10 modern production lines.

Our annual productivity exceeds 1,500,000 pieces or sets.Our factory enjoys the business

pattern of integrating development, production, sale and service as whole. We can produce

over 500 kinds of oil filters, fuel filters, cooling water filters, oil-water separators and

air filters. They are mainly used in engineering machines, heavy duty automotive vehicles,

buses, ships, diesel generating units, air compressors, powder sprays, industrial dusting

and environment cleansing.

These products are sold well in Europe, America, Southeast Asia and Africa.We are

implementing TS16949 system,Each of our products is made strictly according to ISO/TS16949

certificate. We are eager to work together with all our customers based on mutual benefits

towards greater prospects.

Green Filter Service

OUR SERVICE

ZHEJIANG ZHENHANG INDUSTRIAL GROUP CO.,LTD. (Green Filter Factory) has strong

technical strength, advanced production equipment and complete testing means.

Strictly according to IATF16949 system to make high quality level in OEM+OBM+ODM three dimension.

Enterprise provides important technology support for customers by its rich technology experiences,

advanced production equipment and one high-quality human team.

With rich experience and professional technical team, they can match the best filter material

according to the performance requirements of customers. The experienced business team can provide

professional service and docking for customers.

Green Filter Factory

FACTORY TOUR

ZHEJIANG ZHENHANG FILTER TECHNOLOGY CO.,LTD is Located in green valley forest zone- Lishui city.We arespecialized in the development and production of agricultural,constrication machinery and heavy-duty vehicle filters.Ourcompany has strong technicaal strength,advanced production equipment and complete testing means.Strictly according toIATF16949 system to make high quality level in OEM+OBM+ODM three dimension.

Green Filter QC

QC

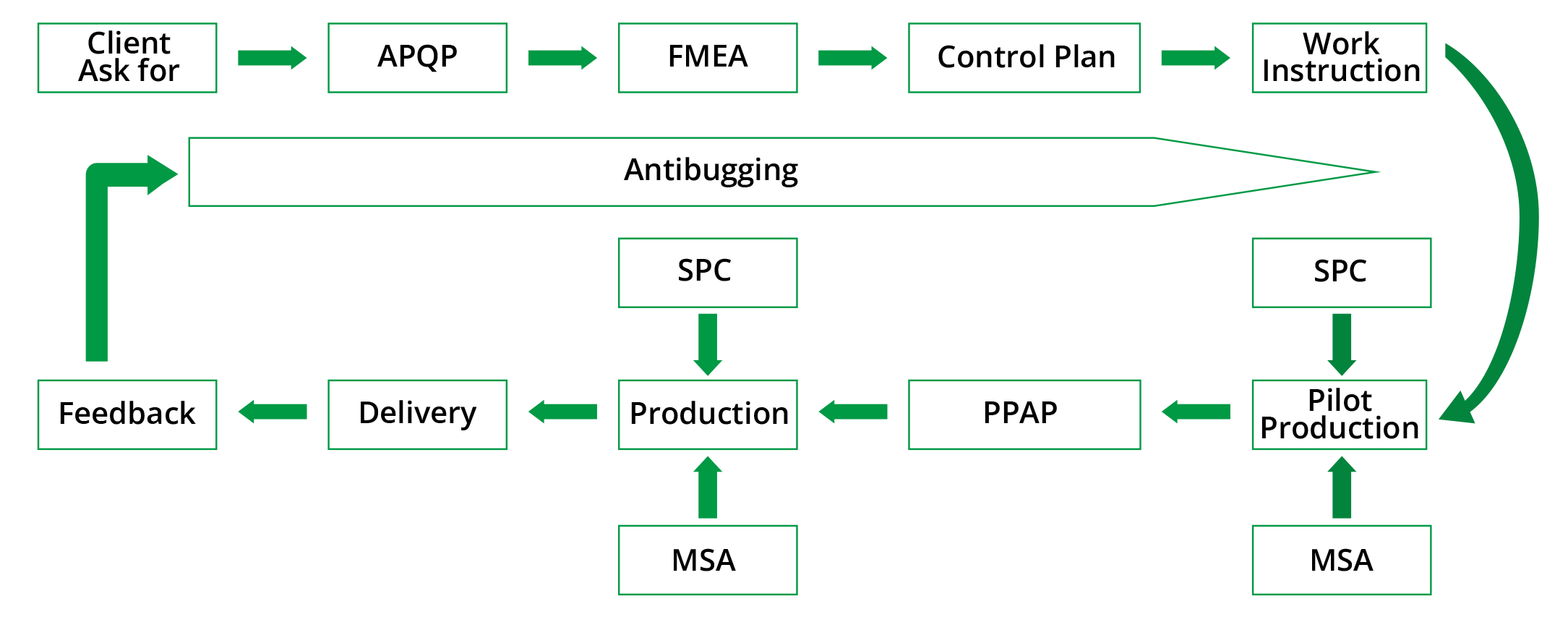

- Apply APQP methods to improve product design and manufacturing process design capabilities.

- Apply FMEA method to eliminate or reduce the occurrence of non-conformity.

- Application of SPC method for process prevention to achieve zero defects.

- Apply MSA method to ensure the reliability of measurement system.

- Apply PPAP methods to ensure that customer requirements are fully understood and met.

- Application of the five tools throughout the core process of product realization.

We carry out advance product quality planning (APQP) according to customer requirements; design potential failure mode analysis (DFEMA) in the product design phase of APQP, and process potential failure mode analysis (PFEMA) in the design of the manufacturing process; the measures taken as a result of FEMA analysis are usually carried out in the control plan for process control, and detailed work instructions are prepared according to the requirements of the control plan. In the trial production stage, the initial process capability study is conducted, and the SPC technique is used to determine the stability and capability of the trial production process; at the same time, the measurement system analysis of the measurement equipment used in the trial production is conducted to determine whether the variation of the measurement system meets the measurement requirements, and the MSA technique is used; after the trial production, the PPAP is submitted to the customer for confirmation and approval. After the trial production, PPAP information will be submitted to the customer for confirmation and approval before the formal mass production; in the mass production, the stability and capability of the process will be continuously studied and monitored; after the delivery of the product, the feedback from the customer will be evaluated, analyzed and improved; throughout the product implementation process, emphasis will be placed on using error-proof methods as much as possible to prevent problems from occurring.

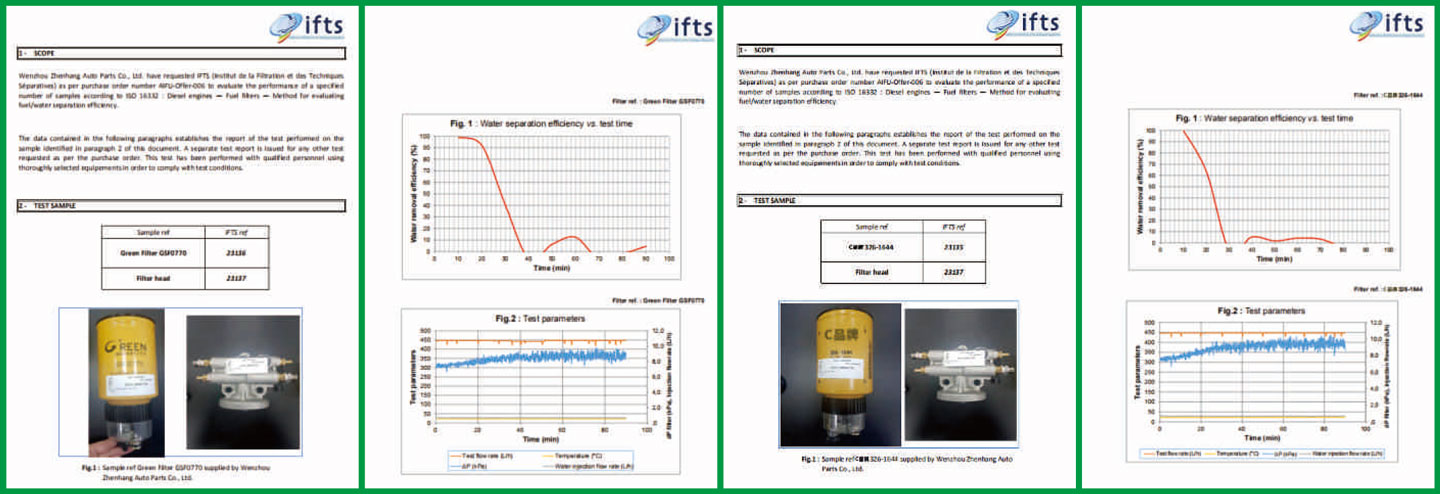

Green Filter Certificate

QUALITY TESTING

Deeply cooperate with intermnational and domestic authoritative experimental institutions to test the performance comparison ofour products and OE parts.